Made-to-measure products

At GrisGroup we enjoy technical challenges.

At GrisGroup we enjoy technical challenges.

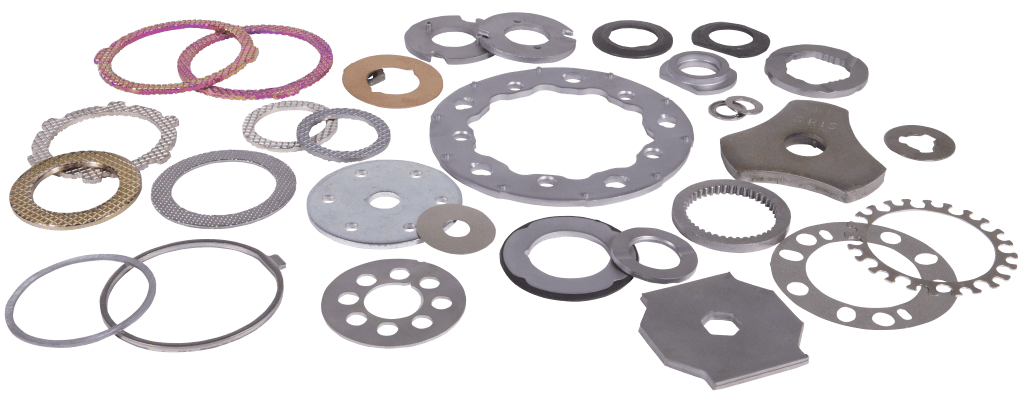

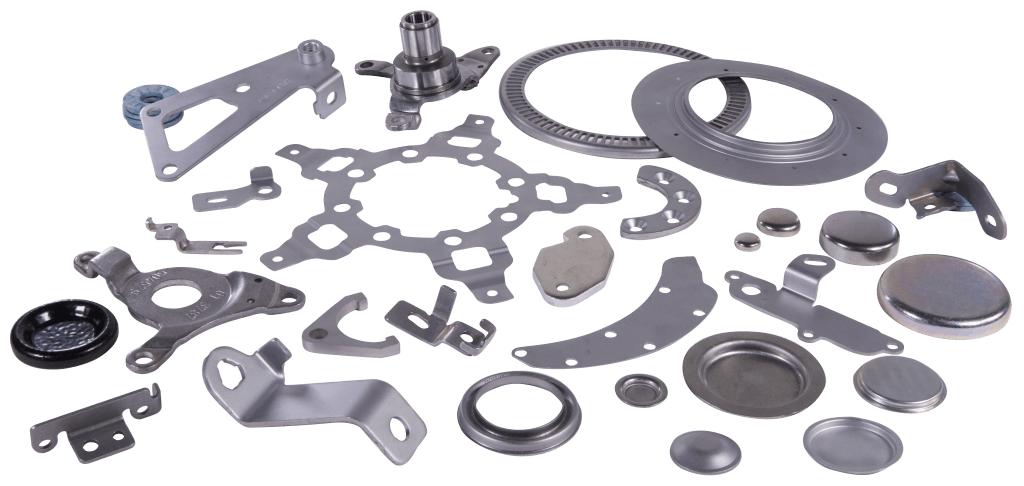

GrisGroup is an expert in the manufacture of complex mechanical components to close tolerances.

Thanks to the complementary nature of its processes (stamping, grinding, tooling, etc.), GrisGroup can support you in the study, design and production of all types of transmission components.

GrisGroup is able to supply all types of complex-shaped, technical metal parts in a wide range of dimensions, for the most diverse applications.

By combining processes, GrisGroup can produce the final shapes of parts without reworking: these parts, with their precise, finished functional surfaces, can be used directly: sizing, tapping, milling, counter-boring, chamfering, crimping studs, etc.

When complementarity and precision work in synergy, production aims for perfection!

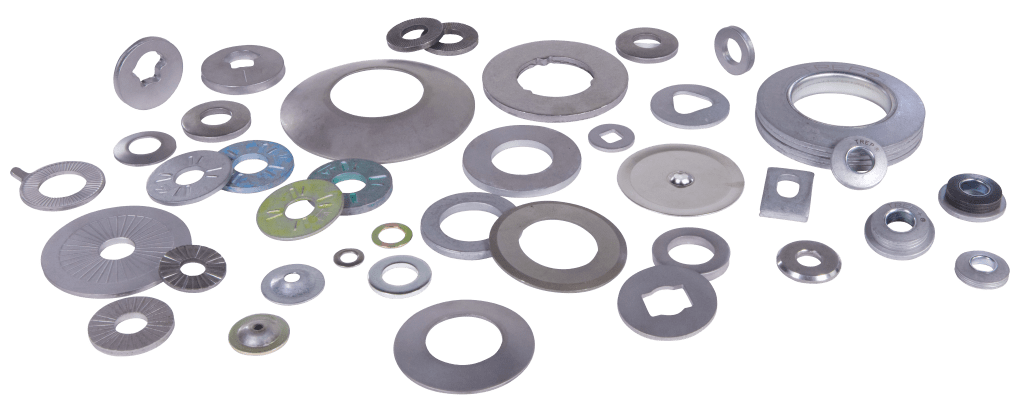

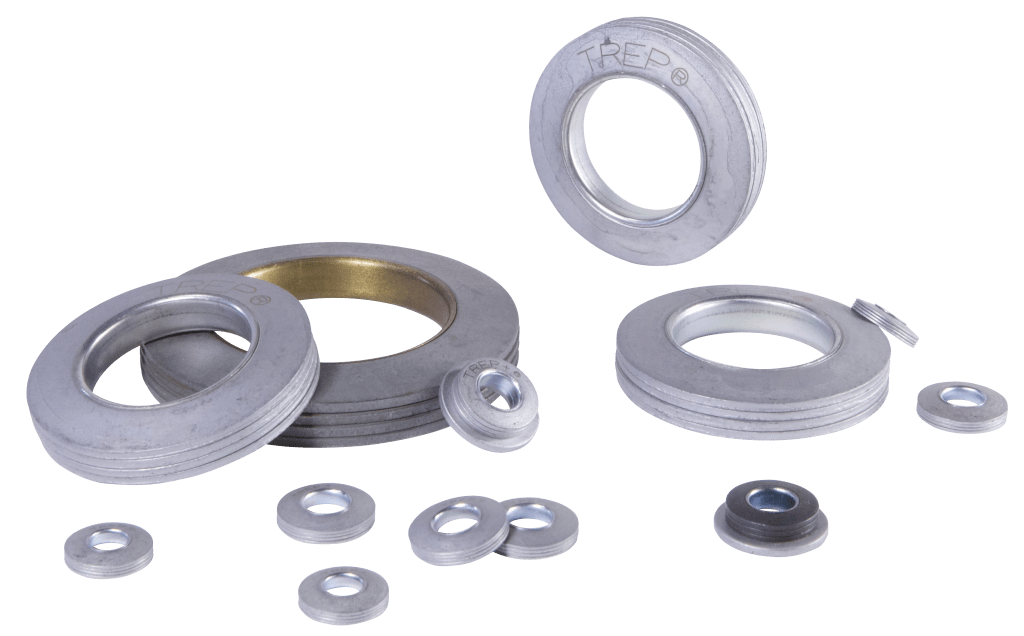

A range of technical fastening washers covering all requirements for bolted assemblies.

GrisGroup is developing its expertise in the design of bolted assemblies. Our products guarantee perfect reliability and a homogeneous, high-performance combination of the various functions of the assemblies.

Guaranteed resistance to loosening, high resistance to unscrewing and suitability for all classes of screw quality make TREP® a unique and exclusive product, and one of which GrisGroup is proud.

We are intensifying our efforts to limit those of your connections!

We’ve said it.